As part of the air conditioning system, the AC Evaporator is a small heat transfer unit located in the dashboard, much like the heater core. However, instead of distributing warm air like the latter, an evaporator contains refrigerant that was cooled down by the compressor. The blower motor pushes air through the evaporator in order to distribute cool air in the passengers’ compartment.

Brief Description

Surface non-condensing water droplets.

Hydrophobic Coatings: Hydrophobic coatings can repel water, preventing the formation of water droplets on the condenser surface. This can be beneficial in applications where water droplets could interfere with heat transfer or where preventing water buildup is essential.

Thickened copper tube.

Thickened copper tubes can enhance heat transfer efficiency. The thicker walls allow for better heat conduction between the refrigerant inside the tube and the air or water outside. This can result in improved cooling capacity and overall system performance.

High conduction efficiency.

In environments with extreme temperature variations, thicker copper tubes can provide better performance and reliability. They can maintain consistent heat transfer even when ambient temperatures are very high or low.

Various of fin styles.

Flat Fins**: These are straight, flat sheets that run perpendicular to the direction of airflow. They are simple in design and are often used in smaller residential air conditioning units.

Louvered Fins**: Louvered fins have a zigzag or V-shaped pattern, which increases the surface area for heat exchange. This design is common in both residential and commercial condensers.

Rippled Fins**: Rippled or corrugated fins have a wavy pattern, further increasing surface area for heat transfer. They are typically found in high-efficiency commercial or industrial condensers

Uniform distribution of fins.

Condenser fins are designed to increase the surface area available for heat transfer. When warm refrigerant gas flows through the condenser coils and comes into contact with the fins, heat is transferred from the refrigerant to the fins. Even distribution of the fins ensures uniform heat transfer across the entire surface of the coils.

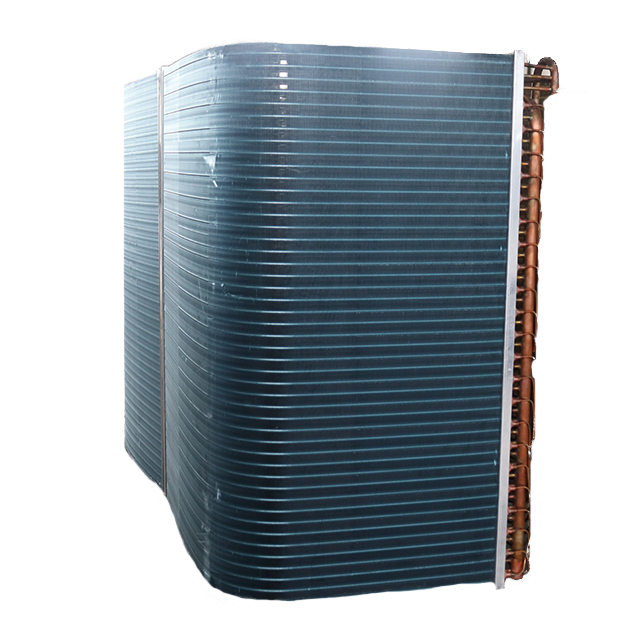

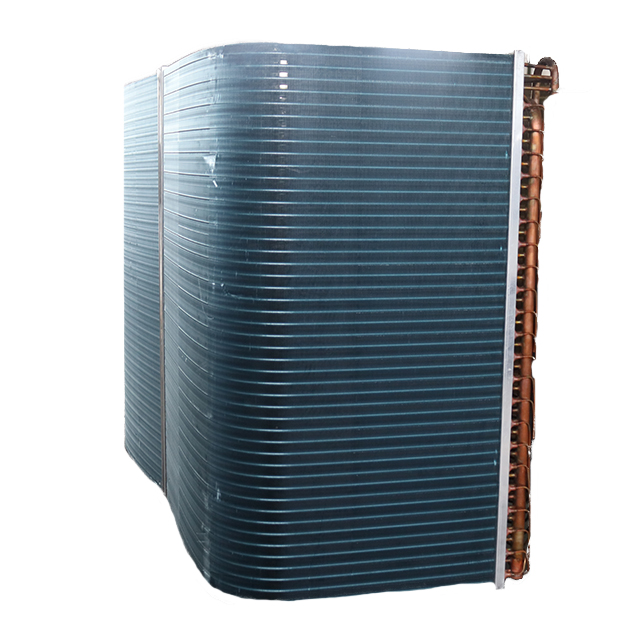

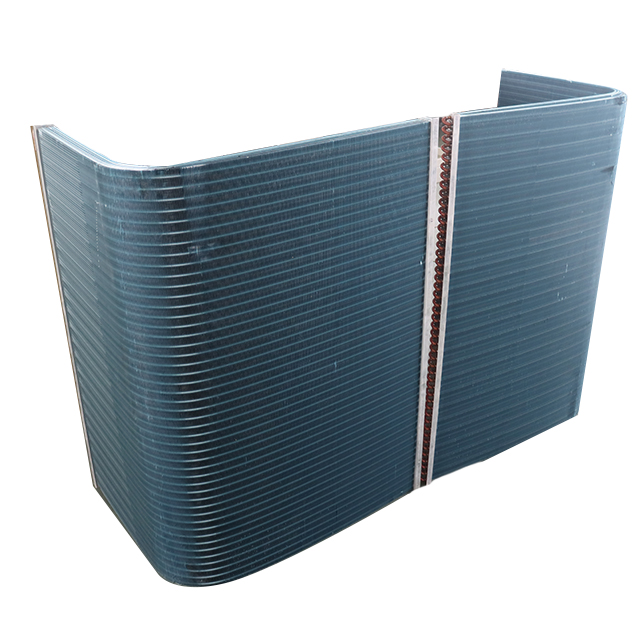

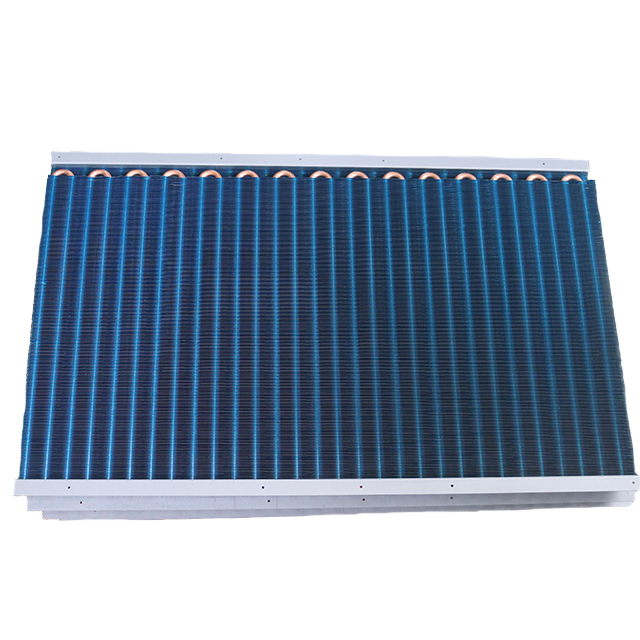

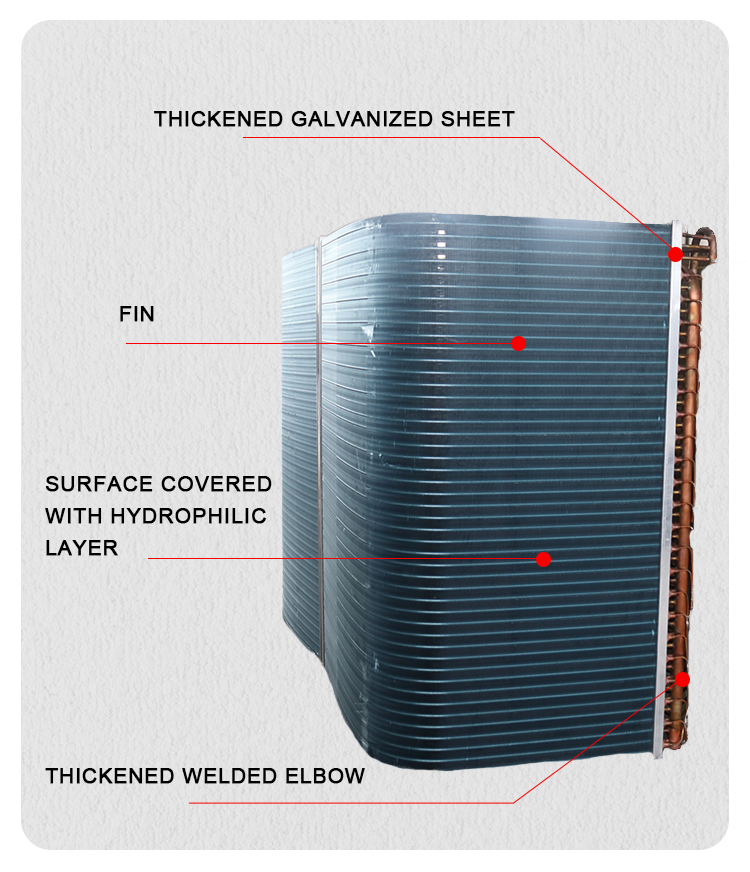

APPEARANCE

The edges of the evaporator are made of thickened galvanized steel frame with fins in the middle, which can be customized for its density and width. The surface of the evaporator is covered with a hydrophilic layer, so that water beads are not easy to stick. Thickened welded elbow is your safety guarantee.

![EVA0DPC0002]()

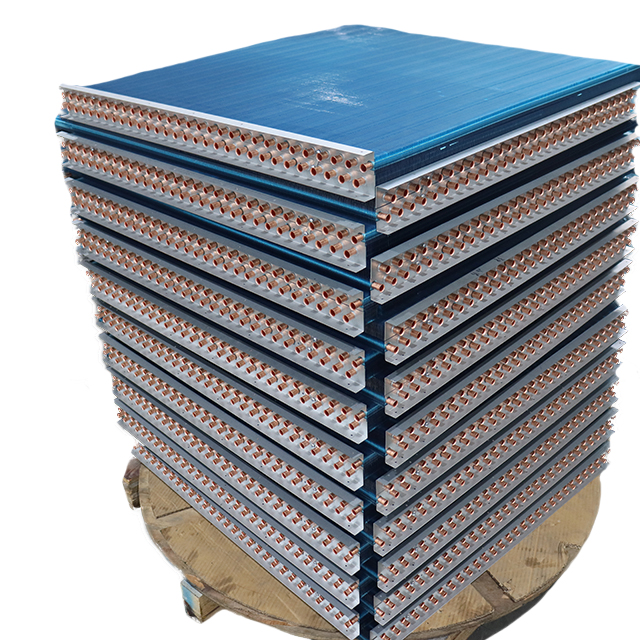

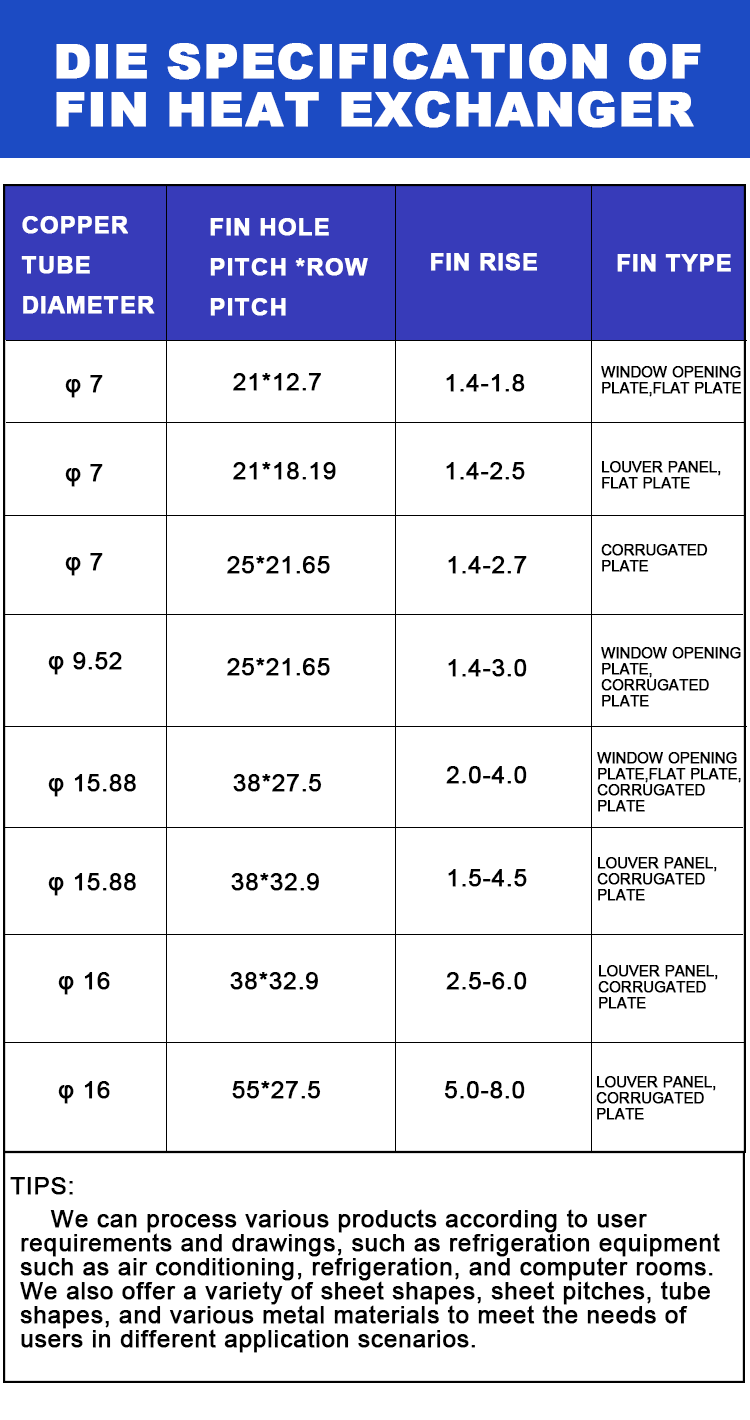

DIE SPECIFICATION OF FIN HEAT EXCHANGER

We can process various products according to user requirements and darwing,such as refigeration equipment such as air conditioning,refrigeration,and computer rooms.We also offer a variety of sheet shapes,sheet pitches,tube shapes,and various metal materials to meet the needs of users in different application scenarios.

![EVA0DPC0003]()

PRODUCT DETAILS

SURFACE NON CONDENSING WATER DROPLETS

The fin surface is covered with a blue hydrophilic layer,and water droplets do not condense on the surface.

THICKENED COPPER TUBE

Good water circulation effect,long usage time,low vibration and noise.

HIGH CONDUCTION EFFICIENCY

The fin spacing design is reasonable,the heat exchange area is sufficient,and the air outlet is smooth and not easy to accumulate dust.

PURSUING QUALITY IN DETAIL

THE ELBOW IS FULL AND BEAUTIFUL

Full appearance,High hardness,Welding firmly

VARIOUS OF FIN STYLES

Can process various products according to user requiements and drawings.

UNIFORM DISTRIBUTION OF FINS

Reasonable spacing,Efficient

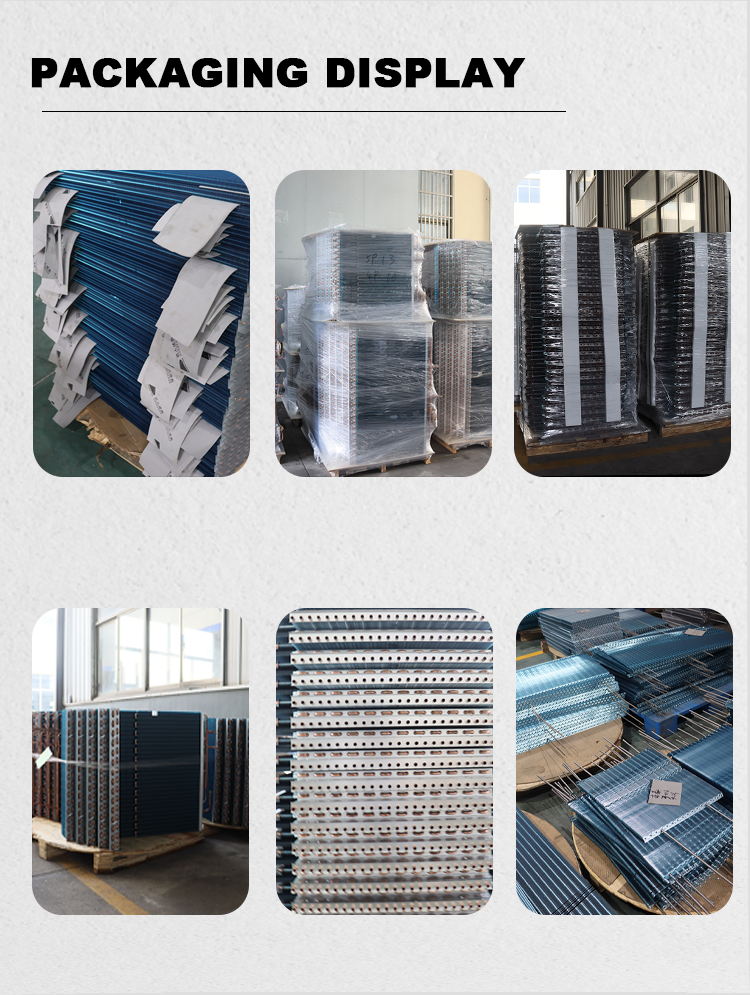

![EVA0DPC0007]()

![EVA0DPC0008]()

FAQ

1.Q:What is your payment terms?

A:TT,L/C AT SIGHT,CREDIT CARD etc

2.Q:What is your delivery terms?

A:EXW, FOB, CFR, CIF etc

3.Q:Are you trading company or manufacturer?

A:Manufacturer

4.Q:May I get a sample?

A:Yes, we can send you 3pieces free samples.

You just charge for the express cost is ok.

5.Q:Can I print my logo?

A:Yes of cause, we accept OEM and ODM.

6.Q:How long is your delivery time?

A:Usually 15-20days, if urgent, we can arrange to do in advance and delivery fast.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

latviešu

Беларуская мова

Български

Esperanto

Basa Jawa

Kinyarwanda

Soomaali

Cymraeg