HVAC Parts are produced by Dabund Pipe since 2008 years.

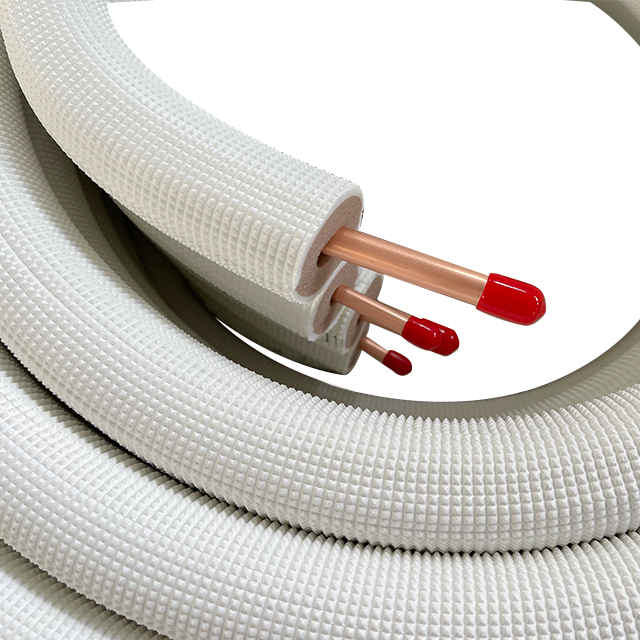

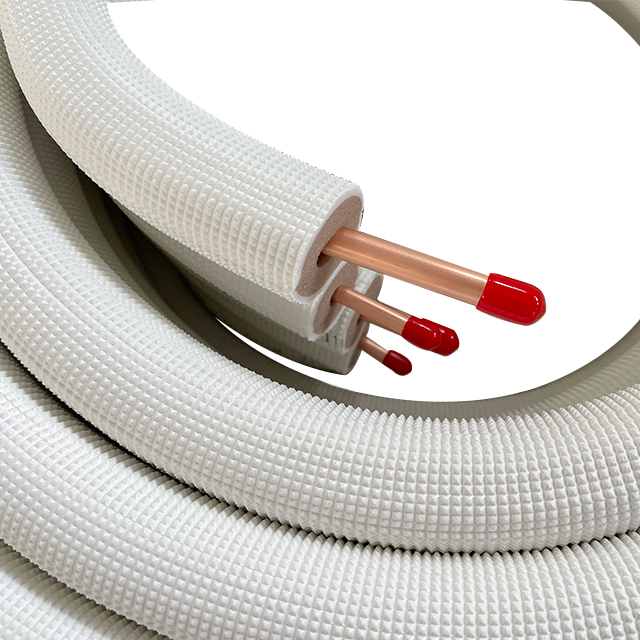

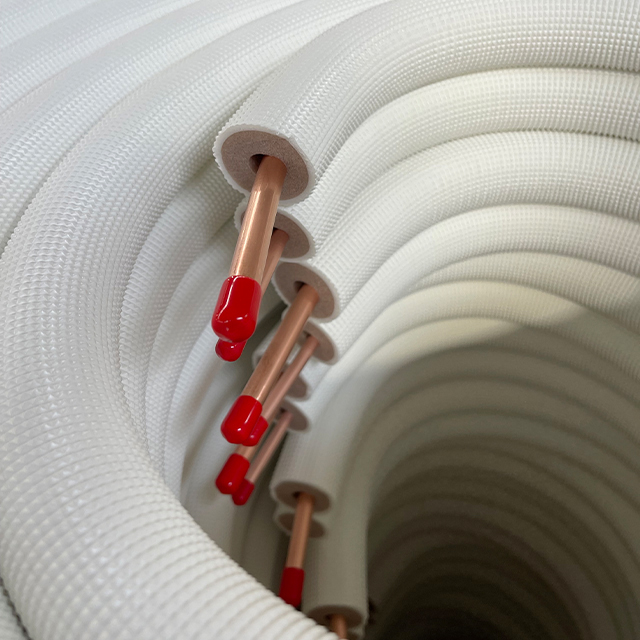

50 ft 3/8“ - 7/8” Insulated copper tubing line set - Seamless copper tube pipe for HVAC. Refrigerant copper tubing pipe insulated with 1/2" white PE insulation.

The insulated copper tubing is twin already. So buy it now.

Product Overview: 50 ft 3/8″ x 7/8″ Pre-Insulated Copper Tube

1. 3/8" x 7/8" is the out dimension in inch. 9.52mm - 22.22mm is the out dimension in metric.

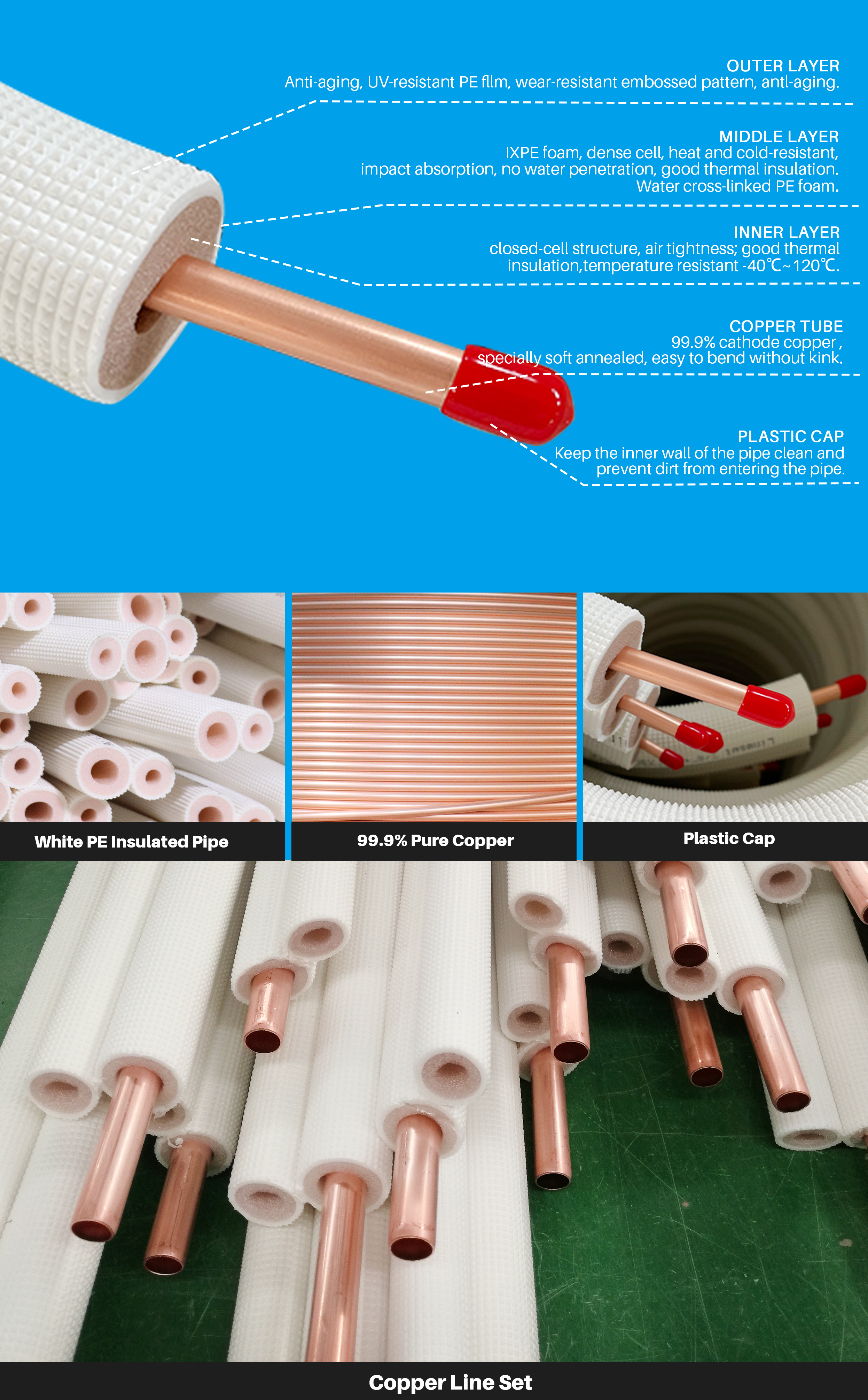

2. 99.9% Pure copper pipe meets ASTM B280 and C12200 standard.

3. AC Copper Size what we can do have following 1/4" 3/8" 1/2" 5/8" 3/4" 7/8" 1 1/8", length can do 15m 20m 25m 30m 50m.

4. Insulation is made of 1/2" Polypropylene & UV Resistant, meets ASTM E 84, UL94, ASTM D1056 and ASTM G 21. Working temperature from -40℃ to 120℃.

5. Works for every Air Conditioning & Refrigeration Application including Ductless mini-split, heat pump and Centralized Air Ducted Units.

6. Pressure Rating: 2100 to 7000 PSI, much more than required 700 PSI for R410.

7. Insulation we produce by ourself, can print your company name, size, meters etc.

Specifications & Quality Standards

Material: 99.9% Pure Copper (ASTM B280 & C12200)

Copper Tube: ASTM B280 & C12200 DHP

Insulation: High density closed cells polyethylene foam

Working Temperature: meets/exceeds ASTM C 1427-07

Dimensions: 3/8″ x 7/8″ (9.52 mm – 22.22 mm)

Surface burning characteristics: UL 94, top-rated for Surface Burning Characteristics – UL 723 Flame and Spread Index less than 25 and Smoke Development Index less than 50

Meets ASTM E84 for smoke and fire (25/50)

Superior tear resistance, UV resistant

Features of pipe insulation tubing:

Key Features of Insulated Copper Tubing

With embossed polyethyene film, climate resistant foam, and thickened insulated cotton, this three-layer insulated mini split copper line set is corrosion-resistant, fireproofing, flame-retarded, thermal insulation, waterproof, shockproof, sound absorption and durable.

High-Performance Insulation with UV Resistance

Outer Layer: Anti-aging, UV-resistant PE fllm, wear-resistant embossed pattern, antl-aging.

Wide Temperature & Pressure Ratings

Middle Layer: IXPE foam, dense cell, heat and cold-resistant, impact absorption, no water penetration, good thermal insulation. Water cross-linked PE foam.

Durable Construction for Long-Term HVAC Service

Inner Layer: Closed-cell structure, air tightness; good thermal insulation, temperature resistant -40℃~120℃.

50 ft 3/8" x 7/8" Insulated Copper Tubing for HVACR Applications Wholesaler & Supplier

DABUND PIPE in-house tested insulate copper tubing and tubing is designed to make installation simple and quick – saving you time and money on each job.

Insulated Copper Tubing

Size | Length | Insulation White PE | Flame Resistant |

1/4+3/8 | 15m/20m/25m/30m/50m | 8mm/9mm/10mm/13mm/19mm/25.4mm | M1/B1 |

1/4+1/2 | 15m/20m/25m/30m/50m | 8mm/9mm/10mm/13mm/19mm/25.4mm | M1/B1 |

1/4+5/8 | 15m/20m/25m/30m/50m | 8mm/9mm/10mm/13mm/19mm/25.4mm | M1/B1 |

3/8+5/8 | 15m/20m/25m/30m/50m | 8mm/9mm/10mm/13mm/19mm/25.4mm | M1/B1 |

3/8+3/4 | 15m/20m/25m/30m/50m | 8mm/9mm/10mm/13mm/19mm/25.4mm | M1/B1 |

1/2+3/4 | 15m/20m/25m/30m/50m | 8mm/9mm/10mm/13mm/19mm/25.4mm | M1/B1 |

3/8+7/8 | 15m/20m/25m/30m/50m | 8mm/9mm/10mm/13mm/19mm/25.4mm | M1/B1 |

1/4 + 3/8 AC line set used for 0.75TON - 1.0TON mini split air conditioner.

1/4 + 1/2 Mini split line set used for 1.5TON - 2.0TON mini split air conditioning.

1/4 + 5/8 Copper line set used for 2.0TON - 2.5TON split air conditioner system.

3/8 + 5/8 Insulated copper tube apply for 3.0TON - 4.0TON ductless mini split air conditioner.

3/8 + 3/4 Insulated copper tubing used for 4.5TON - 6.0TON split air conditioner installation.

3/8 + 7/8 Insulated copper pipe apply for 6.0TON - 8.0TON ductless mini split air conditioner.

Air conditioning copper line sets 1/4 + 3/8 used for 0.75P and 1P split air conditioning.

Copper pipe kit 1/4 + 1/2 commonly used for 1.5P and 2P mini split air conditioners.

1/4 + 5/8 Insulated copper line set used for 2P and 2.5air conditioner system.

3/8 + 5/8 Mini-split copper line set apply for 3P and 4P ductless mini split air conditioner.

3/8 + 3/4 Copper pipe kit used for 4.5P and 6P split aircon installation.

3/8 + 7/8 Insulated copper pipe apply for 6P - 8p TON ductless mini split air conditioner.

1/4 + 3/8 Mini split line set used for 9000BTU and 12000 BTU split air conditioner.

Copper line set 1/4 + 1/2 commonly used for 12000 BTU and 18000 BTU mini split air conditioners.

1/4 + 5/8 Insulated copper line set used for 24000 BTU and 30000 BTU air conditioner system.

3/8 + 5/8 Mini-split line set apply for 36000 BTU and 48000 ductless air conditioner.

3/8 + 3/4 Insulated copper tubing used for 54000 BTU and 72000 split air conditioner installation.

3/8 + 7/8 Insulated copper pipe apply for 72000 BTU - 96000 BTU ductless mini split air conditioner.

Aircon copper line set 1/4 + 3/8 used for 9K and 12K split air conditioner.

High quality copper line set 1/4 + 1/2 commonly used for 12K and 18K mini split air conditioners.

1/4 + 5/8 Insulated copper line set used for 24K and 30K air conditioner system.

3/8 + 5/8 Mini-split line set apply for 36K and 48K ductless air conditioner.

3/8 + 3/4 Insulated copper tubing used for 54K and 72K split air conditioner installation.

3/8 + 7/8 Insulated copper pipe apply for 72K - 96K ductless mini split air conditioner.

Why Choose 50 ft 3/8" x 7/8" Insulated Copper Tubing from DABUND PIPE

We are manufacturer of insulated copper tubing since 2008 years, have good experience of producing and exporting. We have cooperated 9 years forwarder, can guarantee the shipment. Every week we load at least 6-8 40HQ to different countries. Choose Dabund You will win the business.

Individual pre-insulated rolls to perfectly fit every ductless mini-splits, VRF, heat pumps and unitary systems installation.

Quality products with competitive pricing

Peace of mind with professional services

DABUND FACTORY

We produce Insulated Copper Pipe, Mini Split Line Set and Aluminum Pipe and HVAC Parts

SGS Certificate

Mini Split Line Set is made of Polypropylene or Black Rubber with UV Resistant, meets ASTM E 84, UL94, ASTM D1056 and ASTM G 21

Exhibition

We join the exhibitions all over the word, just to facilitate customers to experience our mini split line set face to face.

FAQ

1.Q:What is an insulated copper pipe?

A:An insulated copper pipe is a copper tube covered with a thermal insulation layer, typically used in HVAC, air conditioning, and refrigeration systems. The insulation helps reduce energy loss, prevent condensation, and protect the copper pipe from UV exposure and environmental damage.

2.Q:What are insulated copper pipes used for?

A:Insulated copper pipes are commonly used for refrigerant lines in HVAC systems, including mini-split air conditioners, heat pumps, and central air conditioning units. They are also suitable for refrigeration and some industrial cooling applications.

3.Q:What are the benefits of using insulated copper pipe in HVAC systems?

A:Using insulated copper pipe improves energy efficiency by minimizing heat transfer, reduces condensation and moisture buildup, extends system lifespan, and ensures stable system performance under varying temperature conditions.

4.Q:What insulation material is used on insulated copper pipes?

A:Most insulated copper pipes use closed-cell polyethylene or rubber insulation. These materials provide excellent thermal resistance, moisture control, and UV protection, making them suitable for both indoor and outdoor HVAC installations.

5.Q:Are insulated copper pipes suitable for outdoor use?

A:Yes. High-quality insulated copper pipes are designed for outdoor applications and typically feature UV-resistant insulation that prevents cracking, aging, and degradation caused by sunlight and weather exposure.

6.Q:What sizes are available for insulated copper pipes?

A:Insulated copper pipes are available in a wide range of sizes, such as 1/4", 3/8", 1/2", 5/8", 3/4", and 7/8". Common HVAC line set combinations include 1/4" + 3/8", 1/4" + 1/2", and 3/8" + 7/8", depending on system capacity.

7.Q:Does insulated copper pipe meet HVAC industry standards?

A:Yes. Most insulated copper pipes for HVAC applications are manufactured in compliance with ASTM B280 standards and use high-purity copper (C12200), ensuring safety, durability, and compatibility with modern air conditioning systems.

8.Q:Can insulated copper pipes improve energy efficiency?

A:Insulated copper pipes significantly improve energy efficiency by reducing heat gain or loss in refrigerant lines. This allows HVAC systems to operate more efficiently, lowering energy consumption and improving overall system performance.

9.Q:Is insulated copper pipe easy to install?

A:Yes. Insulated copper pipes are designed for easy installation and are flexible enough for bending and routing. Pre-insulated designs save installation time by eliminating the need for separate insulation wrapping on-site.

10.Q:How long does insulated copper pipe last?

A:When properly installed, insulated copper pipes can last 20–30 years or more. Copper’s corrosion resistance combined with protective insulation ensures long-term reliability in HVAC and refrigeration systems.

11.Q:Can insulated copper pipes be customized?

A:Yes. Insulated copper pipes can be customized in length, insulation thickness, packaging, and branding. OEM and private-label options are commonly available for distributors and HVAC equipment manufacturers.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

latviešu

Беларуская мова

Български

Esperanto

Basa Jawa

Kinyarwanda

Soomaali

Cymraeg